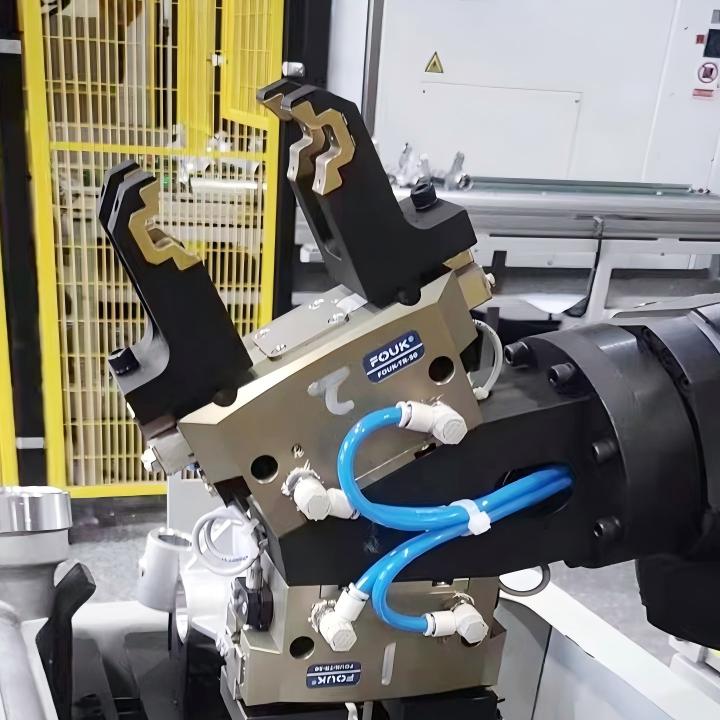

FOUK Product Selection Guide

INTRODUCTION

Pneumatic grippers are mainly used for grabbing, transporting and assembling workpieces, and they feature high strength, large clamping force and short stroke.

Quick selection instructions

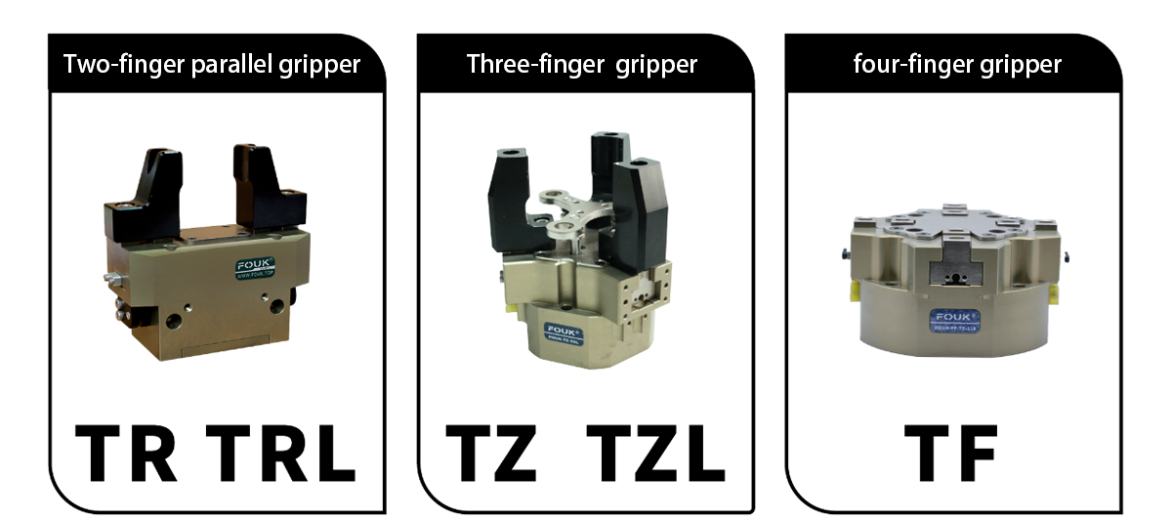

01 Generally, two-finger parallel grippers are commonly used. For gripping circular workpieces, three-finger centering grippers are selected; for gripping square workpieces or in special application scenarios, high-strength four-finger grippers are adopted. Eg, If the workpiece is a round bar and requires horizontal handling, the FR and TRL series two-finger grippers are recommended. |

|

02 identify the gripping requirements

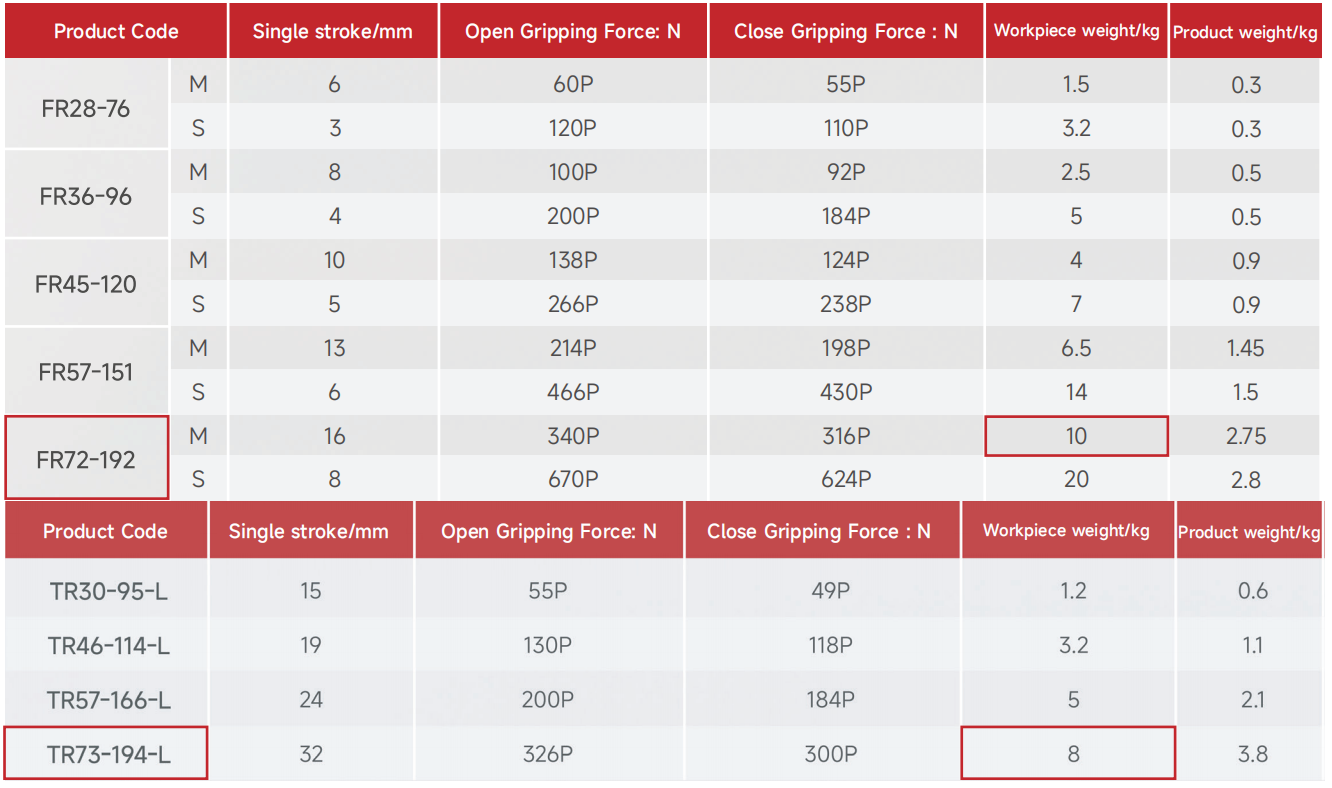

First, identify the type of workpiece that the gripper needs to clamp, and know the weight of the workpiece—then the gripper model can be roughly determined.

03 Consider the size and stroke of the gripper

The size and stroke of the gripper need to match the size of the workpiece. Ensure that the opening and closing stroke of the gripper can meet the requirements for clamping and handling the workpiece.

04 consider the flat grip finger length

When the length of the finger gripper exceeds the maximum allowable clamping distance, the aluminum housing of the gripper is prone to deformation. It is recommended to select a gripper of the next larger model.

Precise selection instructions

01 confirm the gripping requirements

First, clarify the type of workpiece that the gripper needs to grasp and the weight of the workpiece. Select the gripper type according to the workpiece type: two-finger parallel grippers are commonly used for ordinary workpieces; three-finger centering grippers are usually selected for gripping circular workpieces; and powerful four-finger grippers are often used for gripping square workpieces or in special applications. Initially select the appropriate gripper type.

02 select the gripping methods

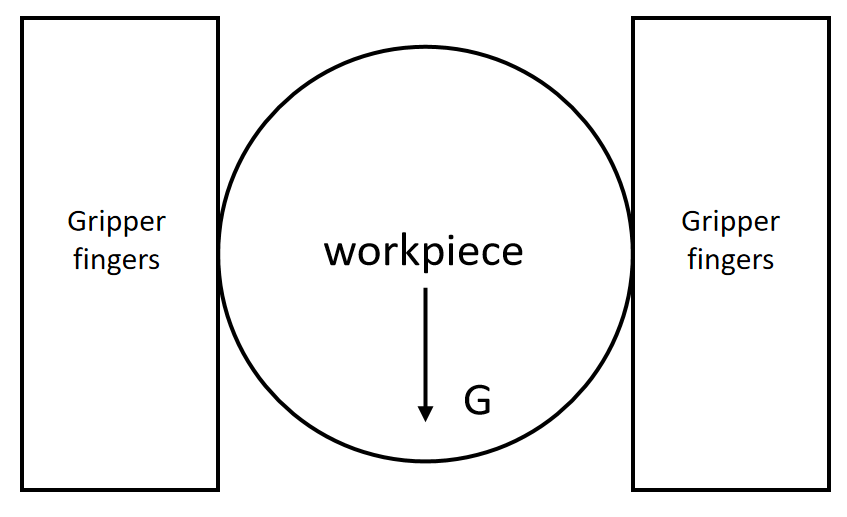

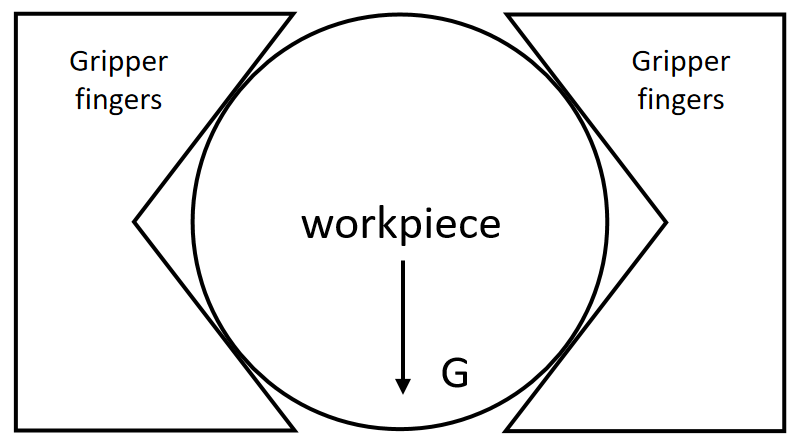

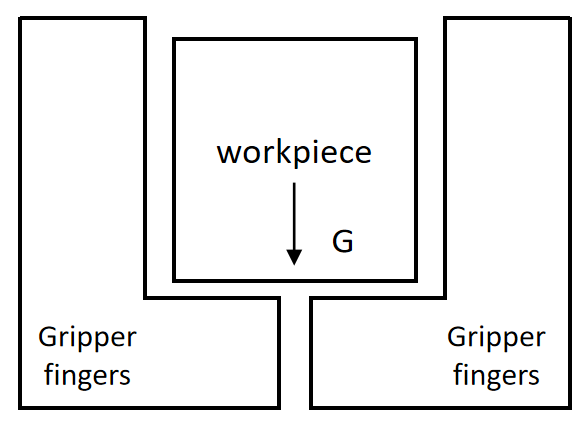

According to different workpiece types, different gripping methods can be selected, which are usually divided into: flat gripping, enveloping gripping, and stepped gripping. Based on the gripping method, a suitable gripper model is further selected.

1. flat gripping It is used to clamp or grab objects in parallel so that they can be operated or moved on a flat surface. During the gripping action, friction provides a stable clamping force to ensure that the workpiece does not fall off during handling. |

|

| 2. Enveloping gripping It clamps objects through clamping force and friction. During the gripping action, the workpiece is gripped by means of friction and supporting force. |

|

3. Stepped gripping It uses a stepped structure to fix objects. During the gripping action, stepped gripping plays a role in preventing the workpiece from falling. The clamping force is provided by friction and stepped supporting force. It can be calculated according to the flat gripping type, and the safety factor S can be reduced during calculation. |

|

03 Consider the gripping force, size, stroke, and finger length.

flat gripper

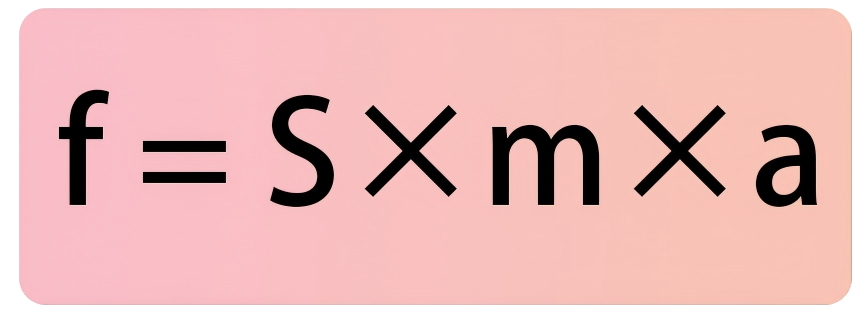

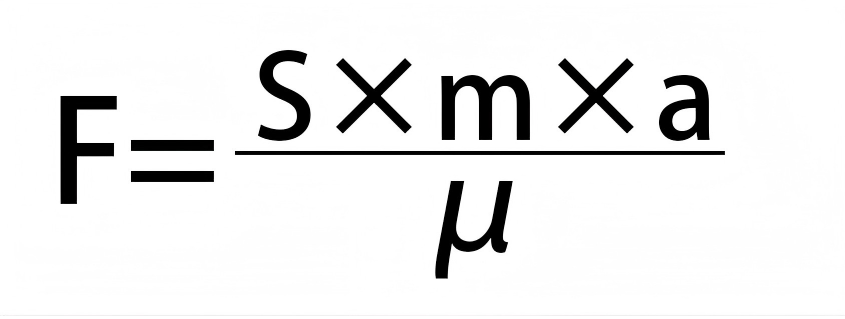

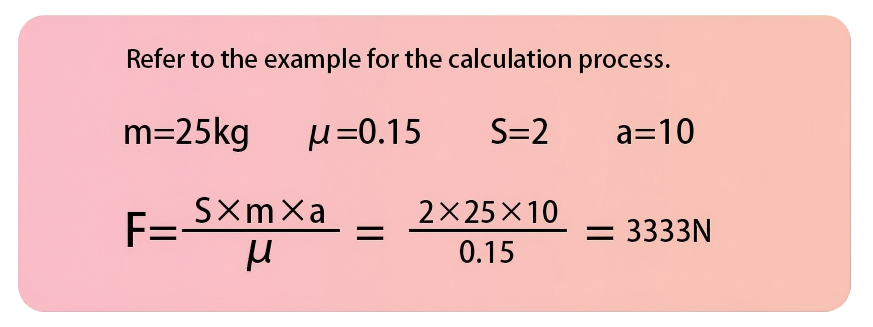

The basic calculation formula for friction force is:

f:friction force

S:safety factor (usually ranging from 1.5 to 2)

m:workpiece mass

a:acceleration (usually ranging from 1 to 2g, where "g" stands for gravitational acceleration)

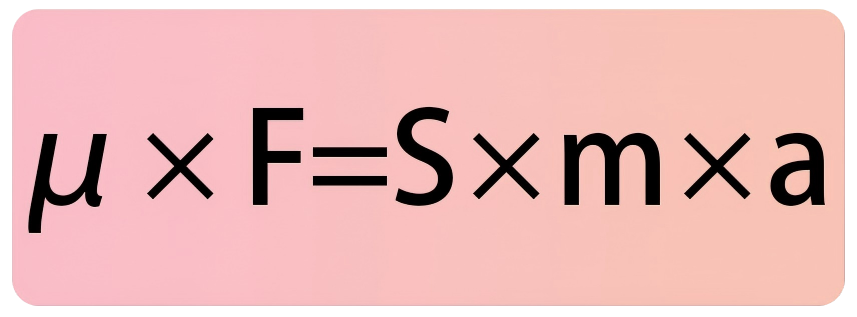

For parallel clamping, the clamping force is provided by friction, which can be calculated using the formula f=μF ;

that is:

So the forcing

Gripper Size and Stroke

After the calculation is completed, when selecting a gripper, it is also necessary to ensure that the gripper’s clamping range can adapt to the size of the workpiece. The opening and closing stroke of the gripper should be larger than the maximum size of the workpiece; except for special cases, the diameter difference of the workpiece should be smaller than the actually required gripper stroke.

Compare whether the clamping stroke meets the requirements and conduct a final confirmation to ensure that the gripper can firmly clamp the workpiece.

Example: If the single-side opening and closing stroke > 20mm, select the gripper model TR115-240.

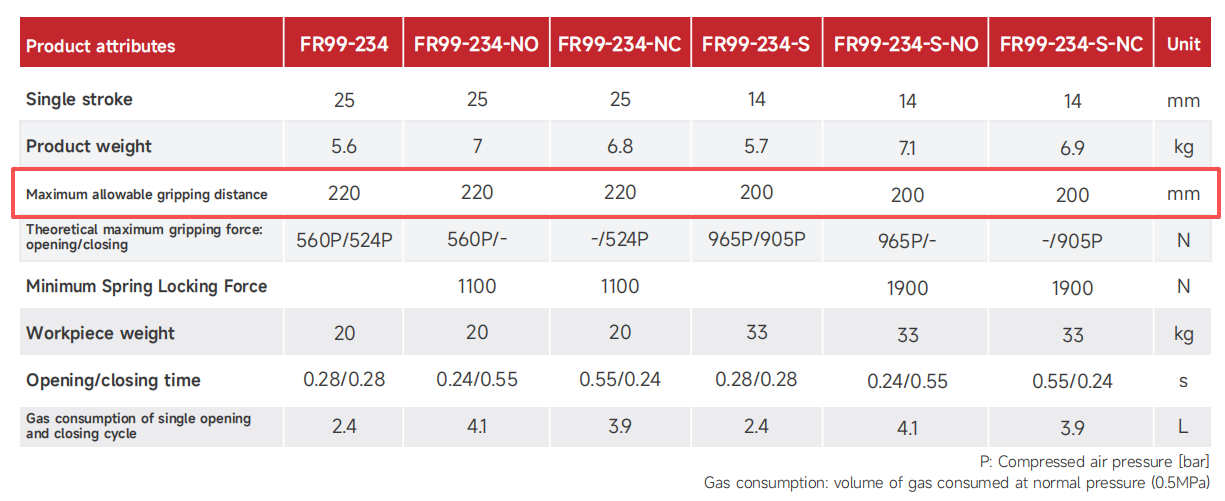

Finger Length

When referring to the clamping force, the finger length of the gripper also needs to be considered. The longer the gripper’s finger length, the smaller the gripper’s clamping force. When the finger length exceeds the allowable usage value, it is recommended to select a gripper of the next larger model.

Through the above steps, the required clamping force for parallel clamping can be calculated, and a suitable gripper model can be selected. In practical applications, it may also be necessary to consider the gripper's installation method, control method, and other special requirements.

Enveloping Gripper

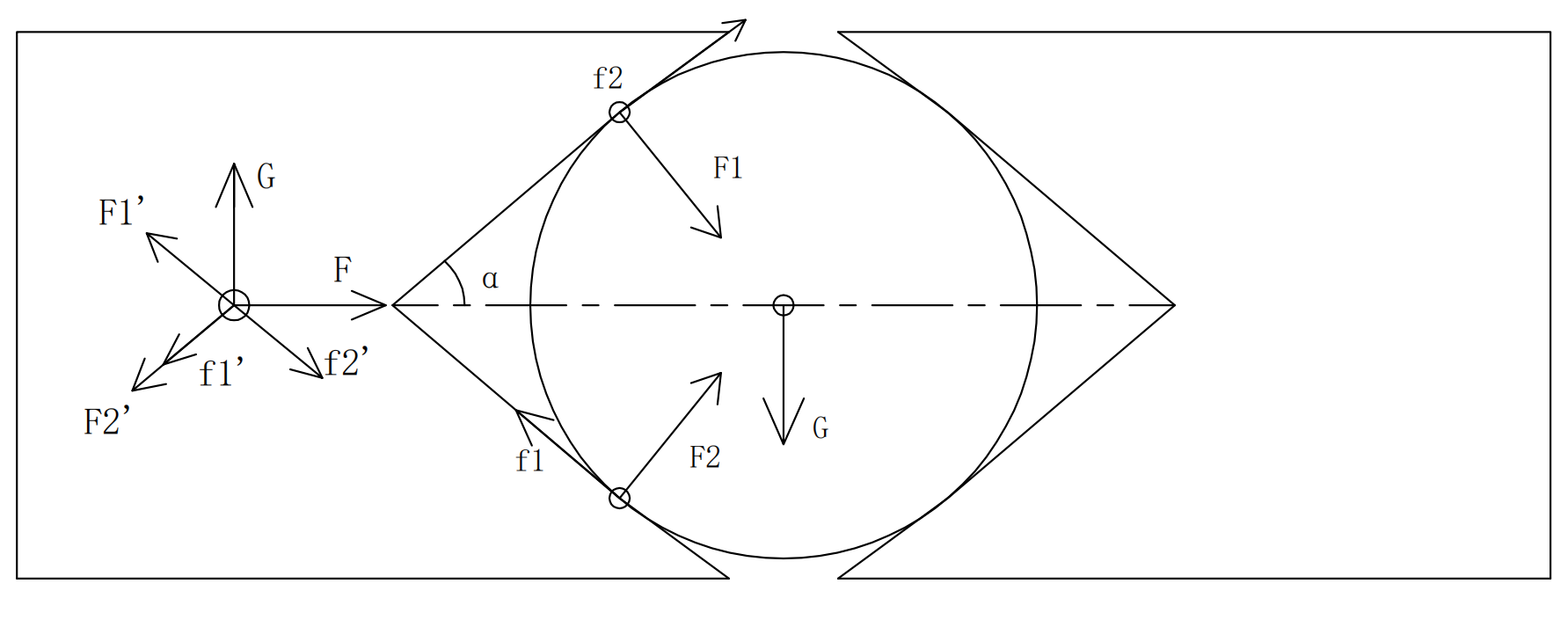

Force Diagram of the Gripping Method of the Gripper

Calculating gripping Force

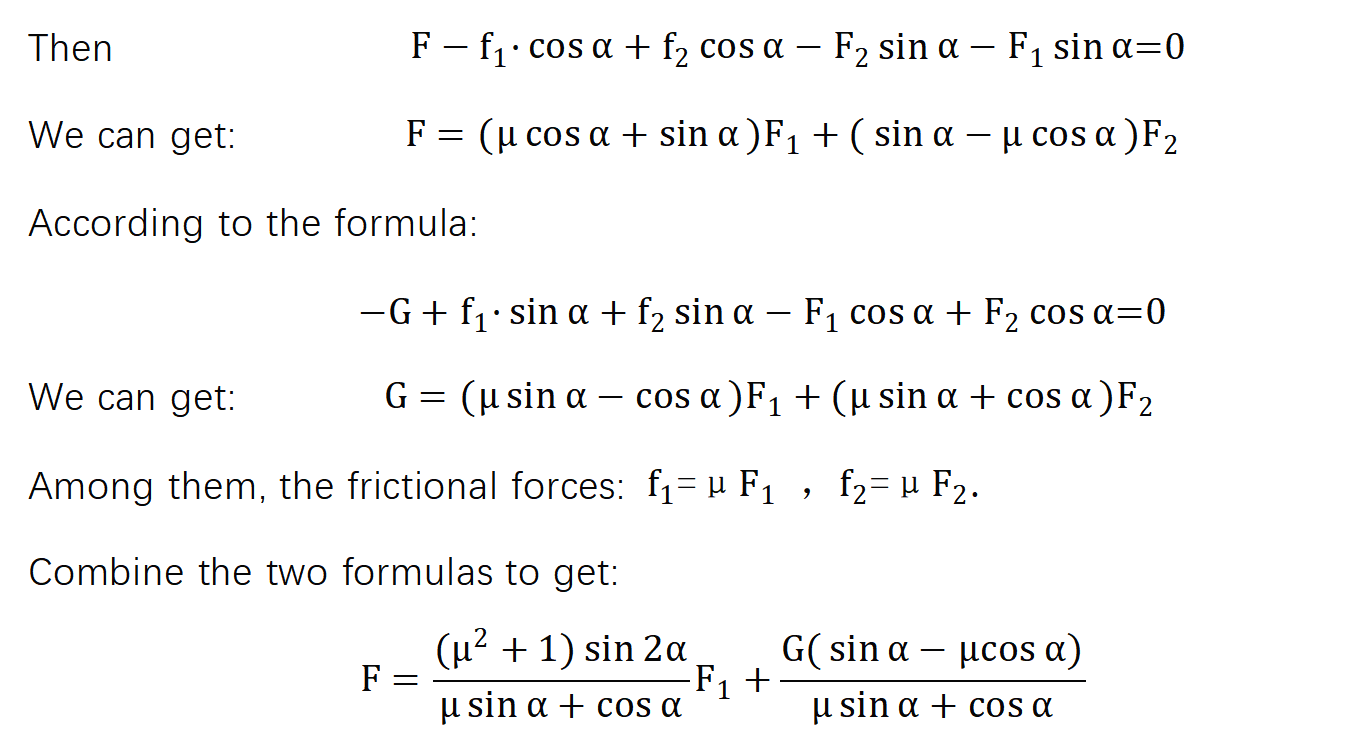

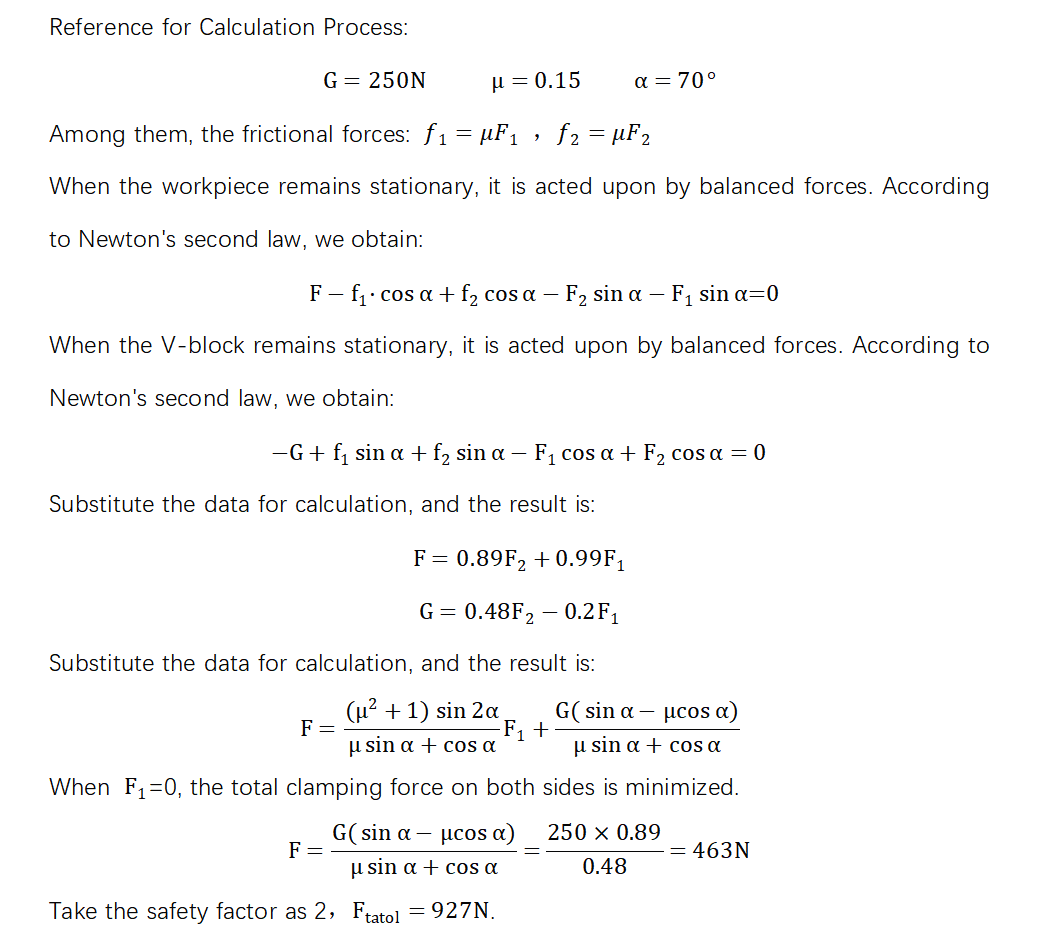

Based on the force analysis diagram, when a round bar is in equilibrium, it is subject to supporting forces F₁, F₂ and gravity G. The V-block on the left is subject to frictional forces f₁, f₂, the clamping force F of the air gripper and the upward pulling force G₁. Since their resultant force is zero, equations can be formulated according to the formula to calculate the magnitude of the clamping force F.

It can be derived from the formula that the smaller F1 is, the smaller the total clamping force F will be. To ensure the reliability of clamping, a safety factor S is usually multiplied on the basis of the calculated clamping force F. This factor generally ranges from 1.5 to 2 to cope with possible unexpected situations or calculation errors. In the calculation, static friction is approximated as dynamic friction, which results in certain errors.

Gripper size and stroke

After the calculation is completed, when selecting a gripper, it is necessary to ensure that the clamping range of the gripper can adapt to the size of the workpiece. The opening and closing stroke of the gripper should be larger than the maximum size of the workpiece. Except for special cases, the diameter difference of the workpiece should be smaller than the actually required gripper stroke. Compare whether the clamping stroke meets the requirements and make a final confirmation to ensure that the gripper can firmly clamp the workpiece.

Finger length

When referring to the clamping force, it is also necessary to consider the finger length of the gripper. The longer the finger length of the gripper, the smaller the clamping force of the gripper. When the finger length exceeds the allowable value, it is recommended to select a larger model of gripper.

Through the above steps, the clamping forces required for parallel grippers and enveloping grippers can be calculated, and appropriate gripper models can be selected. In practical applications, it may also be necessary to consider the gripper's installation method, control method, and other special requirements.